Starch equipment factory 26 years, strive to be the first in the world

European technology Asian price

cassava starch equipment, tapioca powder equipment, garri processing equipment, 100 years equipment supplier

Garri processing factory plays a key part in the economy of tropical countries which mainly treat garri as their main food. There are two kinds of garri: white garri and yellow garri. The difference between white garri and yellow garri is that the yellow garri is made with palm oil and cassava. While, garri processing factory not only statisfies people’s needs in the tropical countries, but also brings economic effect. The next is the deatails of garri processing factory.

Cassava processing mahine

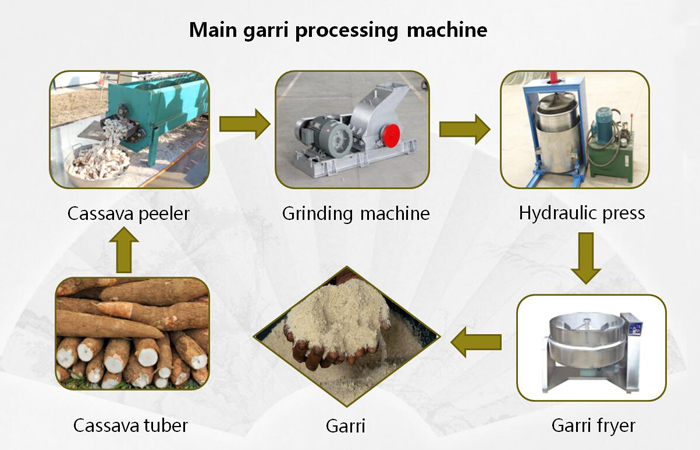

Garri processing factory mainly production process includes cassava cleaning section, cassava peeling section, cassava grinding section, cassava fermentation, garri dewatering section, garri frying section, garri sieving and packing machine.

1, Cassava cleaning section in garri processing factory mainly includes cassava cleaning part and cassava washing part. The cassava are first cleaned by dry sieve. The dry sieve rotates its inner spirals to push cassava rotating, thus some surface dirt will be cleaned. Then cassava will be washed by paddle washing machine. Paddle washing machine rotates its paddle, cassava will flow in the countercurrent against water. After the two steps, cassava almost are remved its surface impurities.

2, Cassava peeling section in garri processing factory is mainy done by cassava peeling machine. Cassava peeling machine can make cassava peeling rate above 95%. Therefore, the peeling machine can peel cassava with high effeciency.

3, Cassava grinding section in garri processing factory is mainy done by cassava grating machine(click this to see the grating machine working video). The capacity of the grating machine can be adjusted according the amount of cassava. The Cassava garri grating machine is made up of machine cover, box, engine base, principal axis,hammer and mesh pieces. And there are different models for choosing.

4, Cassava fermentation is after cassava grinding section in garri processing factory. Those cassava which are have been grinded should be put into bags for fermentation. After fermentation the taste of garri will be improved. The fermentation should last for two or three days.

5,Garri dewatering section in garri processing factory is done by hydraulic press. The machine uses the priciple of hydraulic press to squeeze the water of material and discharge out of charging barrel. It is mainly used in small scale garri processing plant.

6, Garri frying section in garri processing factory is done by garri fryer(you can click this to see the garri fryer working video). The fryer is a automatic frying machine, which can control its tempreture in case of pasting phenomenon. The machine has large capacity. Due to heat fast, the machine shorten the time of garri processing.

7, Garri sieving and packing section in garri processing factory mainly include garri vibration sieving machine and garri packing machine. garri vibration sieve has different screen mesh, as a result, Some large particles of garri can be sifted out.

These are the main sections of garri processing factory. Certainly these are just main part of garri processing factory. There are different size factories, therefore, these factories have different capacities. Accordingly, SIDA Company can design the machines according to the amount of garri`s output. Besides, SIDA Company has professional team to guarantee the quality of garri processing machines.

PREV:Period !

NEXT:Period !