Starch equipment factory 26 years, strive to be the first in the world

European technology Asian price

cassava starch equipment, tapioca powder equipment, garri processing equipment, 100 years equipment supplier

Processing Capacity:20-200Tons/day

Application Scope:Manufacturers of Cassava starch processing machinery

WhatsApp:phone22

Phone:phone22

Email:hoan366@hotmail.com

Wet cassava starch is produced by traditional cassava processors either as a direct product or as a by-product resulting from cassava processing into other products such as gari, fufu e.t.c. Post-harvest loss is high for cassava roots due to the inadequacy of the traditional processing method and inability to convert cassava into less perishable products. To reverse this trend, there is a need to mechanize cassava processing. In Nigeria, mechanized cassava processing is still on the developmental stage and the potential is very high.

Cassava starch processing machinery

Here are the introduction of the detail cassava starch manufacturing process in cassava starch production plant

1.Raw material preprocessing: The shelf life of cassava is very short. Unfavorable storage conditions can result in loss of starch, which, in the worst case, can lead to the death and breakage of raw materials, which is detrimental to the overall process. Therefore, the roots should be processed in the order they are sent to cassava starch production plant, and the roots must be processed within 24 hours of harvest. Besides, raw materials of bad quality have to be rejected.

2.Raw material cleaning and washing: The first point to process the cassava is cleaning. Dry sieve is widely used for cleaning in cassava starch production plant whose main function is to remove sand, mud, leaves and other debris. Then the paddle wash machine is used for washing process which combines flushing with a low water level and continuous removal of dirt and peels. The wash water may be recycled after filtering off peels on a rotary screen and settling of sand in basins. Process water from the refining station and crude water replace the loss of wash water.

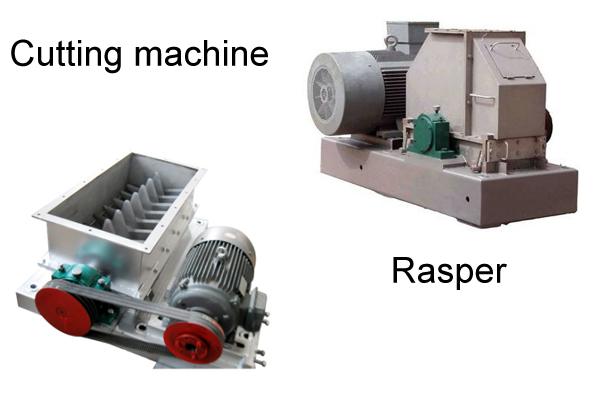

3.Cassava cutting and crushing: The washed cassava tubers are conveyed through conveyor belt to the cutting machine. In this section in cassava starch production plant, the cassava roots are chopped into pieces so as to ensure a properly feeding into the resper. Crushing is an key factors which determines the extraction rate of cassava starch. SIDA rasper fully absorbs advanced technologies from home and abroad whose breaking rate is more than 94%.

Cassava cutting and crushing machine

4.Centrifugal filtering: Another main factor which influence the extraction rate in cassava starch production plant is the filtering process. The centrifuge sieve and fine fiber sieve are adopted for this process. And the high efficiency of these machine makes it feasible to utilize high quality sieve plates made of stainless steel, which will withstand abrasion and CIP-chemicals.

5.Desanding: The specific gravity of mud and sand is greater than that of water, and is also larger than that of starch granules. Hence the separation of sand out of starch slurry by gravity separation is effective. Desander is a machine serves for this purpose in cassava starch production plant.

6.Hycrocyclone refining: Hycrocyclone station is a cassava starch production machinery used for concentration, refining and washing the starch slurry so as to achieve the purpose of removing the protein, cell sap and other impurities in cassava starch production plant. The extraction is a counter current process. With hydrocyclone station it is possible to reduce protein and cell sap to low levels with a minimum of fresh water. The color or whiteness can be ensured by this process.

Cassava starch refining machine

7. Dewatering: The purified starch milk is then dewatered on a batch operated peeler centrifuge in cassava starch production plant. The required moisture content after dewatering is below 40%. SIDA peeler centrifuge can effectively decrease the moisture content to 38%,and the siphon type peeler centrifuge can achieve a 36.5% dewatering effect.

8.Drying and packing: The dewatered starch is then dried by flash dryer with high speed air flow in cassava starch production plant. Special cooling system is adopted to guarantee the uniformity of the final starch. And finally, the dried starch is packed into different specification for selling.

SIDA Company is a professional enterprise specialize in designing and manufacturering cassava starch machine, we have experienced technical personnel to provide the first-class craft and the mechanical design, tailor-made machine to suit your cassava starch production plant, and provide the turnkey service for you.

Aerial view of the factory

The cassava processing line manufacturing process of AD company has got praise from European customers.