Starch equipment factory 26 years, strive to be the first in the world

European technology Asian price

cassava starch equipment, tapioca powder equipment, garri processing equipment, 100 years equipment supplier

Cost of cassava processing equipment in nigeria-cassava processing machines manufacturers

Henan sida has decades of professional manufacturing experience of cassava starch processing equipment. We have many kinds of starch processing machine with high-quality. After months of hard work, sidaCompany have designed a complete equipment infrastructure map, production workshop layout diagram including starch production line details and other professional technical data. Since we are professional in cassava starch processing machines manufacture and installation, so we finally got the chance to provide the cassava starch processing machines for them.

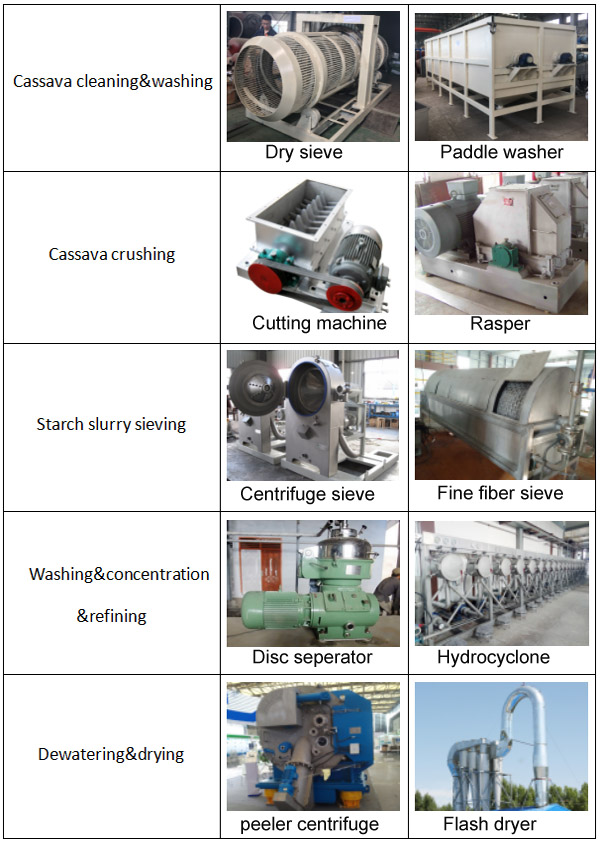

1.Cassava cleaning and washing section

Dry sieve: dry sieve will rotate its inner spirals to remove some impurities and peels of cassava. This part will guarantee the high quality of cassava starch. It's worth to tell you that our cassava starch machinery won't destroy the cassava body in this cleaning process, keep the starch yield.

Paddle washing machine: this machine is a different washing machine compared with potato starch washing process. It adopts counter current washing principle to make raw material flows in the converse direction against water. In cassava starch machinery, the two are designed according to the requirements of local clients.

2.Cassava cutting and crushing section

Cassava cutting machine: used to cut cassava into pieces, convenient for further crushing.

Cassava rasper: rasper can crush cassava with high extraction rate. rasper has features of modern design, compact structure, high speed and high rasping coefficient. In cassava starch machinery produced by other countries, hammer mill will be used, but the machine has lower extraction rate. Our cassava starch machinery make the starch extraction rate more than 94%.

3.Cassava residue and starch separation

Centrifuge sieve: The machine can extract cassava starch, this step is a key part in cassava starch machinery, used to remove fibers out of starch slurry.

Fine fiber sieve: The machine remove small fiber which can not be separated by centrifuge sieve. After this machine, cassava starch will become purer. Our cassava starch machinery in this section has front and back washing system, which can wash the mesh so as to guarantee the normal operation.

4.Cassava starch concentration, washing and refining:

Disc separator: the machine is used to separate protein, cell liquid out of slurry, and it can be used for enrichment and purification of starch slurry. Usually it is matched with hydrocyclone to concentrate and wash cassava starch.

Hydrocyclone unit: in the cassava starch machinery, hydrocyclone is used to remove fibre, protein and cell sap out of starch milk to concentrate and delicate scrubbing starch milk. Usually hydrocyclone unit includes concentrating, recovering and washing. After processed by this section, the cassava starch milk will be pure enough.

5.Cassava starch dewatering

Peeler centrifuge: this cassava starch machinery is used to dehydrate cassava starch, has siphon and adopts centrifugal force, so cassava starch can be dewatering with high efficiency.

6.Cassava starch drying

Flash dryer: the machine has special heating system and cooling system. Besides, the machine adopts negative pressure system which can guarantee clean working environment. It is also an effective dryer of cassava starch machinery.